Bridgestone launches waste tire recycling pyrolysis test

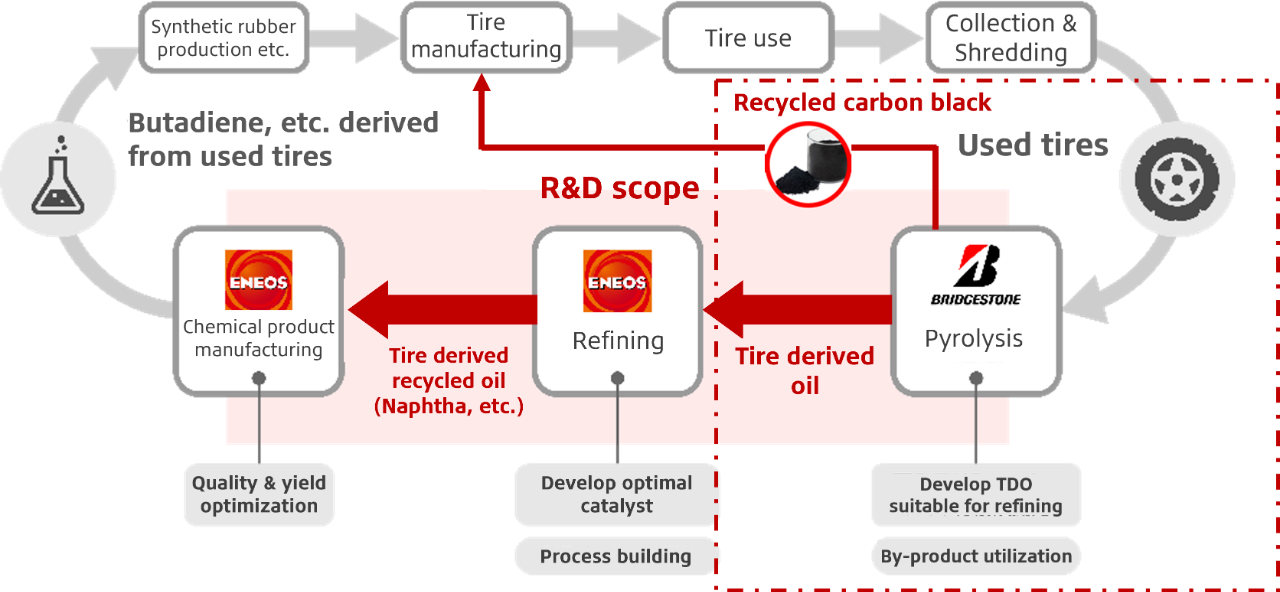

On June 8, Bridgestone announced that it had begun to use the test device installed in Bridgestone Innovation Park in Tokyo to produce tire derived oil and recovered carbon black through pyrolysis. The initiative aims to promote the implementation of chemical recovery technology to enable accurate pyrolysis of waste tires.

This project is one of the two R&D programs promoted by the New Energy and Industrial Technology Development Organization (NEDO) of Japan to develop chemical product manufacturing technology using waste tires, and is part of the NEDO Green Innovation Fund.

As part of the joint project with ENEOS, Bridgestone is currently promoting the verification test of the project. The technology research and development of producing butadiene and other chemical products through the refining tire derived oil obtained from ENEOS precise pyrolysis. ENEOS has crude oil refining technology and basic chemical product manufacturing technology, as well as Bridgestone's precise Pyrolysis technology, and has advanced rubber and polymer material design technology.

According to the project, large-scale verification test will be promoted by 2030, with the goal of realizing large-scale production. The first step to achieve this goal is to use the test device to produce tire derived oil and recover carbon black through Pyrolysis.

As a sustainable solution company, Bridgestone has developed its unique sustainable development business model in all the "production and sales", "use" and "regeneration" stages of its Dan Totsu products to ensure that sustainable development is integrated into the nature oriented business model.

Bridgestone launched EVERTIRE INITIATIVE in April 2022. This plan aims to shape a better future and accelerate the transformation to a sustainable solution company by co-creation with various partners, recycling used tires to produce new tires and returning rubber and other raw materials, called the Eternal Tire (EBERTIRE).